Our Projects

Demanding Marine Operations is a core of the maritime industry. Today, the time frame with a new design or an alternative procedure with respect to e.g. anchor handling, platform supply, subsea installation, or buoy mooring operation transferred to industrial and academic teams may easily be up to 2 - 3 years. Introducing a more simulation-driven design process, by developing simulator models simultaneously with the design of a new ship, procedure or equipment, will accelerate lessons learned and allow more alternatives to be tested. Furthermore, this will improve the effectiveness of the prototype innovation processes, which is typical for the Norwegian maritime cluster, and strengthen the regional education.

Our project vision: “A strong Norwegian maritime offshore industry through world leading competence and knowledge in the fields of simulation based design and simulation of complex maritime operations”.

Primary objective: Develop next generation simulator as an open, standardized framework and architecture for virtual prototyping of deck machinery, which will be a new platform for product development and operations in the maritime industry.

Goals of our research on maritime applications include:

- Contribute to the strategic development at Aalesund University College towards a key actor for innovation, testing, and training in demanding marine operations.

- Enable the industry to implement simulation-based deck machinery design, enable more efficient communication between the customer, designer and product developer throughout the design process.

- Promote research competence of NTNU i Aalesund with cooperated national and international partners, and strengthen research activity in the university colleges’ demanding maritime operation areas of expertise and academic responsibility.

- Promote educational competence of NTNU i Aalesund on MSc and PhD level, training of PhD candidates and MSc students within the scope of the project is a prioritized activity, to make a significant contribution to the academic and industrial cluster’s ability to achieve their objectives in terms of knowledge generation, recruitment of PhD and MSc candidates, and international collaboration.

- Bridge building between industry and research, and between various disciplines and academic environments, to acquire new know-how by employing MSc and Ph.D. candidates with experience in simulation-oriented work-flow and virtual prototyping.

The Norwegian maritime industrial cluster is a world leader in developing complex, customized ships and offshore vessels to the global market, particularly ships for demanding and complex operations, where safety and environment are focused areas. The Møre regional maritime cluster on the west coast of Norway is focused on marine offshore operations. The industry with more than 200 companies and 20,000 employees has a complete value chain of expertise and activities, including design, building, equipping and operation of advanced offshore vessels and devices.

Leading know-how on systems and operational modelling/simulation is of vital strategic importance for this industrial cluster in order to further strengthen their global competitiveness. Development of high performance maritime ships and deck machinery for demanding advanced marine operations is the strategic core locally and nationally. Advanced control and usability allowing for efficient and safe operations is the key differentiator. For the maritime industry, sales will be increased due to an increased quality of maritime equipment and vessels.

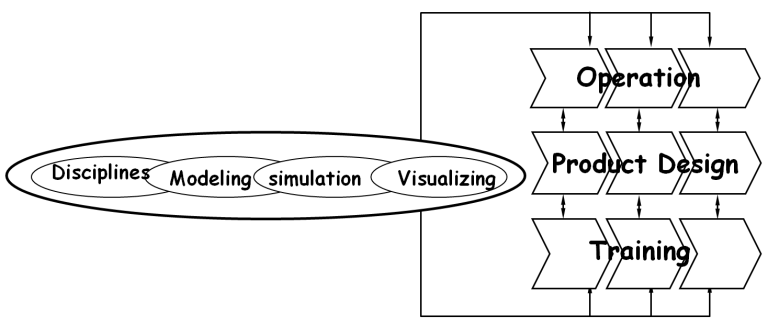

NTNU i Aalesund has reorganized the research strategy to support the maritime offshore operation industry. This research is to develop a virtual prototyping framework for deck machinery system design, allowing for the configuration of all subsystems, including mechanical sub-system, control sub-system, hydraulic sub-system and verification of operational performance as a part of the design process. The developing simulation environment concept for design, testing, training, and education is shown in Figure 1.Developing such a system could integrate engineering design, control theory and hydraulic performance in such a way as to allow the virtual prototyping environment to provide pre-testing, fault finding, error investigating, and operation verification functions. The results from the project will generate new opportunities for collaboration and allow for more efficient work processes, thus improving the technological level and productivity of the maritime industry.

Developing such a system could integrate engineering design, control theory and hydraulic performance in such a way as to allow the virtual prototyping environment to provide pre-testing, fault finding, error investigating, and operation verification functions. The results from the project will generate new opportunities for collaboration and allow for more efficient work processes, thus improving the technological level and productivity of the maritime industry.